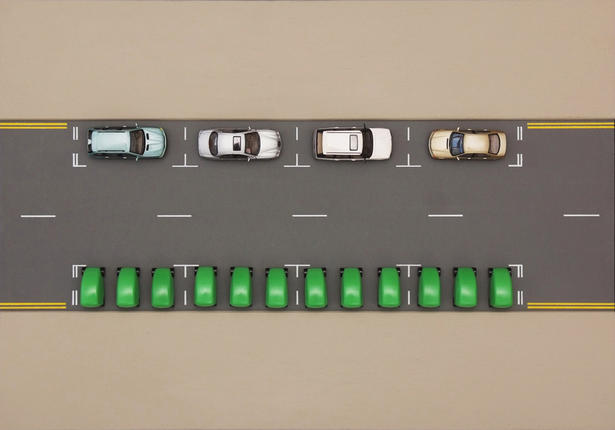

Gordon Murray Design Limited, celebrating 1 year of operation, announced the completion of the first half of the development of the Gordon Murray T.25 city car. The Gordon Murray T.25 city car is a vehicle designed to reduce congestion and the environmental impact of the cars. For example, three Gordon Murray T.25 city cars can fit into 1 standard UK parallel parking space.

The Gordon Murray T.25 will be Euro 4 compliant and the first prototype will be built starting early next year.

Gordon Murray Design Limited Press Release:

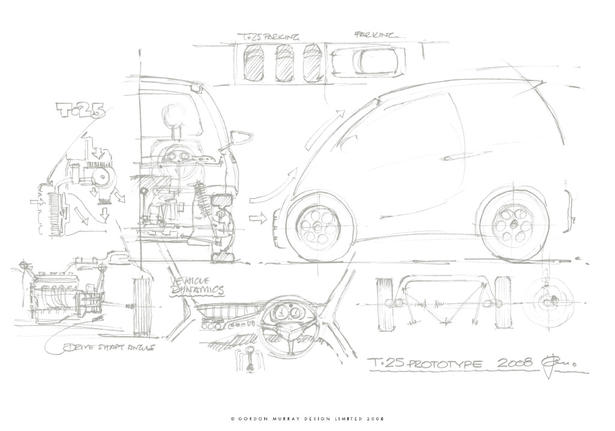

The T.25 program is at mid-point with 12 months

work completed in the 24 month program. Work carried out to date is meeting schedule and budget targets and the progress on design is showing that the weight and cost targets are also on track.

The most exciting aspect of this milestone in the program is that ‘real world’ quotations for the new manufacturing process have shown that all the ambitious targets for a massive reduction in manufacturing, running and lifecycle CO2 damage reductions will be met or bettered.

Component design is almost complete with the first prototype build scheduled to begin in early 2009.

The T.25 program is not just about innovative vehicle packaging and lightweight design, it also offers solutions to reduce congestion and parking problems whilst addressing the problem of full lifecycle CO2 damage.

The manufacturing process is a complete re-think on the way we build cars and will revolutionise automobile production.

The T.25 is designed to protect our mobility, personal freedom and driving ‘fun’ whilst greatly reducing the environmental damage from vehicle manufacturing and running.

In short, the T.25 architecture, packaging and manufacturing process promises to be the biggest revolution in the mass production of cars in the last 100 years.

Interest in the T.25 program has been world-wide and Gordon Murray Design is currently in

discussion with several prestigious companies and groups regarding both the sale of the T.25 program for volume production and other versions of vehicles using the same manufacturing process.

SIZE AND STRUCTURE:

• The T.25 will not be just a small ‘big car’ but will have a radically innovative architecture and the flexible layout will support a variety of uses.

• Its compact size will allow ‘2’ T.25’s to travel in one UK motorway lane. Trebling the capacity and reducing congestion.

• ‘3’ T.25’s can easily fit into ‘1’ standard UK parallel parking space, trebling much needed urban parking, reducing pressures for inner

cities as well as the disruption to traffic flow.

• Delays caused by congestion are prominent in urban areas and easing or eliminating existing congestion on the road network would be worth some £7-8 billion of gross domestic products per annum.

• The compact size of the T.25, being half the size of the average car, will still achieve the highest safety standards (at least 4* Euro NCAP).

• T.25 will have a better power-to-weight ratio than the average 2 liter luxury saloon. Reversing the trend towards larger, heavier and more powerful cars.

• Accident repair costs are kept low by way of replaceable body panels.

LIFE CYCLE IMPACTS:

• The T.25 will be best in class with CO2 emissions and fuel consumption less than half of the

UK average.

• The vehicle program is a complete re-think on high volume materials and the manufacturing

process, and will lead to a significant reduction in CO2 emissions over the lifecycle of the car

from ‘cradle to grave’.

• Component parts will be minimised through multi-functional component design and careful

consideration of tooling requirements.

• Minimal parts and the compact size will support low cost manufacture and will significantly

reduce life-cycle impacts.

• Materials selected will be made from recycled materials where possible and will have the

lowest life cycle impact that meets design requirements.

• The compact size will reduce correspondingly any energy used in raw material extraction

and manufacture.

• The compact size will also reduce the size of site needed for final assembly and manufacture.

Reduced components will decrease energy used during tooling and fixture manufacture.

• The T.25 chassis is designed to “flat pack” for transportation. During transportation, the

compact size will enable 12 times as many T.25 ‘body-in-white’s’ to be shipped in a standard

shipping container as compared to a average car ‘body-in-white’. Again more vehicles can

be transported with any other means of transit, further reducing energy usage.

• In view of the fact that the vehicle will be light, the tires should experience minimal wear,

thereby extending their overall life which will in turn reduce the problems associated with the

disposal of used tires.

• At end-of-life, many components will be re-usable including the body and chassis.

POTENTIAL MARKETS USAGE:

• The T.25’s unique selling points will make it attractive to a range of markets.

• Having low to zero emissions should qualify the owner for reduced operating costs e.g.

exemption from congestions charges, low VED etc, making it attractive to the urban market.

• The size benefits and turning circle will greatly facilitate access, parking and reduce road

blockages making it attractive for inner city use.

• The base version of the T.25 will have a purchase price which will be at the lower end of the

UK market.

• Cities are currently responsible for 75% of global emissions and are increasingly looking to

introduce low emission and congestion related measures e.g. London, Paris and New York.

• The T.25 standard architecture will offer MPV flexibility by incorporating six different layouts

in one package.